Definition and Production Process:

Tempered glass is produced by heating the glass to approximately 650°C–700°C and then rapidly cooling it. This thermal process induces compressive stress on the surface and tensile stress inside the core. As a result, tempered glass becomes 4 to 5 times stronger than standard annealed glass. When broken, it shatters into small, blunt fragments, minimizing the risk of serious injuries.

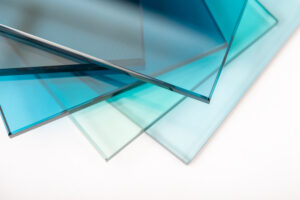

Technical Specifications:

- Thickness Range: 4 mm – 19 mm

- Minimum Size: 300 x 300 mm

- Maximum Size: 2400 x 4500 mm

- Color Options: Clear, Smoked, Green, Bronze, Blue, Frosted (on request)

- Edge Options: Ground, polished, C-edge (optional)

Applications:

- Façades and curtain walls

- Glass doors and partitions

- Shower enclosures

- Furniture and shelving

- Staircase and balcony railings

- Automotive windows

- Elevator glass panels

Advantages:

- High impact resistance

- Thermal resistance (tolerates temperature differences up to 250°C)

- Breaks into harmless pieces

- Long-lasting and safe

Important Notes:

- Cutting, drilling, or edge processing is not possible after tempering.

- The glass must be fully shaped and processed before tempering.